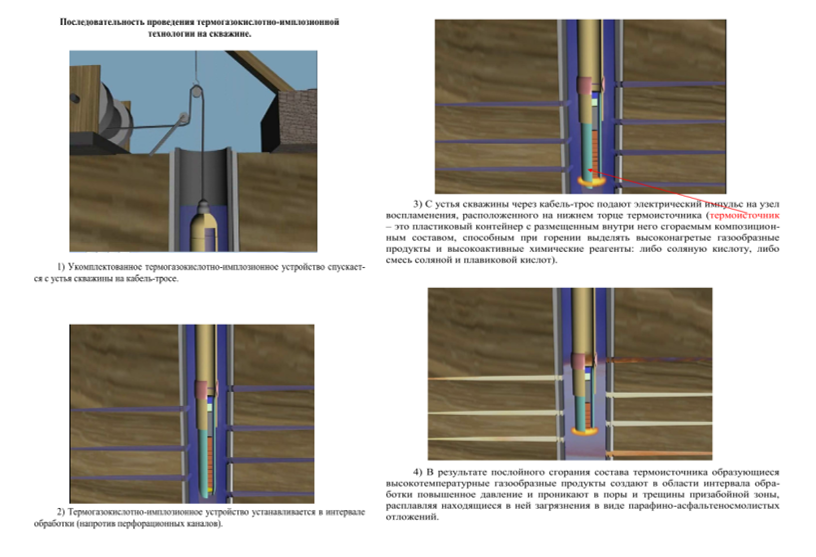

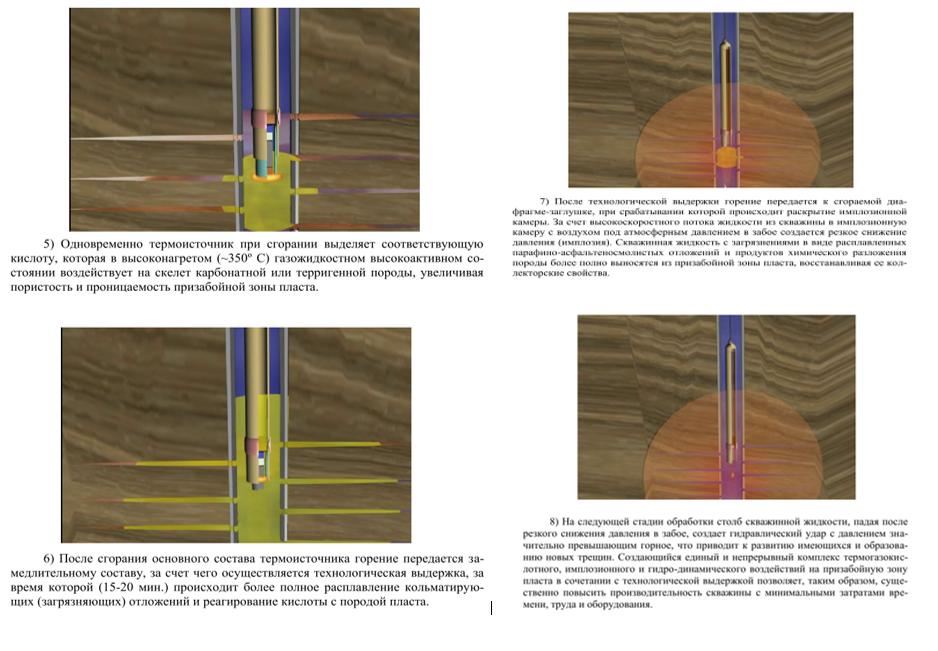

The technology is designed to restore or increase the flow rate of oil wells where oil inflow was reduced during operation and injection processes to increase injectivity. Universal, almost the only ones and unique sources of energy and chemical agents for well treatment technologies are energy-saturated materials that represent gas-burning composite materials. The function of the device is based on the release of energy and agents as a result of the chemical combustion reaction directly at the well bottom.

A special feature of thermo sources made of composite materials based on ammonium nitrate and epoxy compound is their explosion safety and the ability to simultaneously create high or higher pressures, temperatures and gaseous products in the same process operation, including those consisting mainly of active high-temperature chemical reagents, for example , hydrochloric acid or mud acid.

Due to the fact that during the operation of the thermo source in the well treatment interval, high energy parameters and intensive processes of influence are created, in order to ensure the efficiency of the treatment, a substantially smaller amount of agents is required, as compared to the known methods. In addition, all the energy released by the device directly in the treatment zone is consumed, unlike existing technologies, with virtually no losses.

Accordingly, such technologies have high ecological safety, because all chemical agents start to be released only in the treatment zone, then they are consumed and neutralized directly within the treatment interval of the bottomhole formation zone.

On the other hand, the energy-saturated composite materials used in the technology are not only sources of energy and chemical agents, but possessing high strength characteristics, can serve as a structural member in devices that make it possible to create pulsed, wave, overburden or underburden, as well as hydraulic influences.

This provides a wide combined treatment with high parameters of almost all existing types of influence (pressure, temperature, chemical) on the bottomhole formation zone

TASKS HANDLED:

- Gas-hydrodynamic, thermal and chemical effects in the bottomhole zone during the well operation;

- Formation of new fractures in the bottomhole zone;

- Under the influence of high temperature asphaltene sediments are melted, formed in the bottomhole zone during the well operation;

- Improvement of physical and chemical properties of oil in the desired direction;

- Chemical effect on the reservoir (hydrochloric acid treatment).