The perforating jobs are designed to create channels in a casing (one or multiple), cement stone and a part of rock contaminated with mud particles while drilling the well in order to provide pressure communication between the formation and the well.

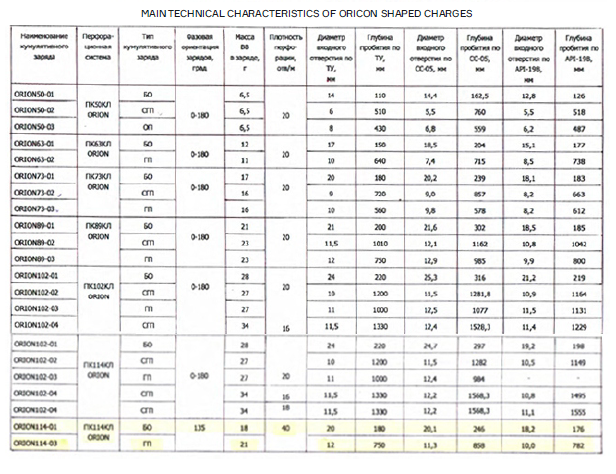

Formation secondary fracturing is one of the most important operations affecting the further effective operation of oil and gas and gas wells. Most of the work on the secondary fracturing of oil and gas bearing formations is currently carried out using cumulative perforation. Depending on the task in hand, as well as well conditions and the reservoir bed characteristics, cumulative, drilling or hydromechanical perforations can be applied.

Case cumulative single-use perforators are cable run into the borehole. After one shooting, the case of the device breaks down and is retrieved together with the explosion products. The equipment is used in cased wells filled with liquid that is used in wells filled with gas or gas condensate.

TASKS:

- Separation of formations in exploratory wells in need of surveying upper horizons;

- Isolation of the object in production and injection wells when passing to the above objects;

- Creation of artificial bottomhole;

- Cutting off the perforation interval when surveying column integrity.

Tubing Perforating Jobs

The perforation of cemented well bores (liners) in comparison with slotted, wire, perforated uncemented liners enables to minimize the risk of uncontrolled leakage of hydraulic fracturing fluid into the formation (depending on the length of the perforated interval).

Advantages:

- Simplicity of arrangement, no risk of insufficient integrity of installed packers (crossflows between zones);

- The number of ports is not limited by the internal diameter of the casing liner, the dimensions of the baffle and the sequence of balls with increasing sizes;

- No risk of fracture breakthrough between sections;

- No washing out of a significant mass of the propant during the bottomhole normalization;

- Possibility to isolate fractures after breakthrough of the water front

Disadvantages:

Increased working pressure friction losses are possible as the liquid passes through the shaped holes:

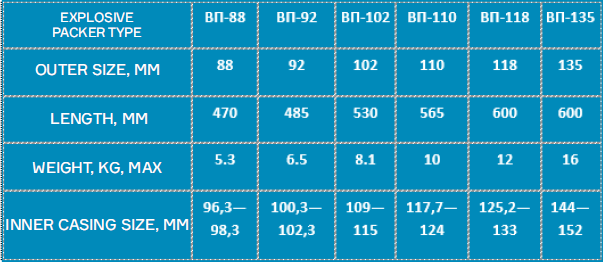

Explosive Packer Installation

- The installation of cement plugs is used to obtain a stable water-gas-oil resistant cement stone column of a certain strength for transition to the overlying horizon, side tracking, strengthening the unstable and cavernous part of the well bore, testing of the horizon using the reservoir tester, well overhaul and preservation or abandonment.

- When an explosive packer is installed, a VP and VPSH packer is used (slips explosive packer).

Smoke gun powder charge is used as a packer charge. The ignition of the charge is carried out by an electric igniter such as TEZ-3P or EVPT by current feed through the cable from the surface. Running into hole is carried out on KOBD-4, KOBDT-4 type cable